Background

GRAT Automation Solutions provide critical electric ball valve solutions for railway insulator washing vehicles, which are essential for maintaining electrified rail systems. By addressing limitations of traditional manual or pneumatic valves—such as low precision, slow response, and poor environmental adaptability—GRAT's DN65 and DN125 pipeline solutions significantly enhance automation and reliability in regular cleaning operations that ensure insulation performance and operational safety. These solutions are now widely deployed across public railway networks.

Operating Conditions

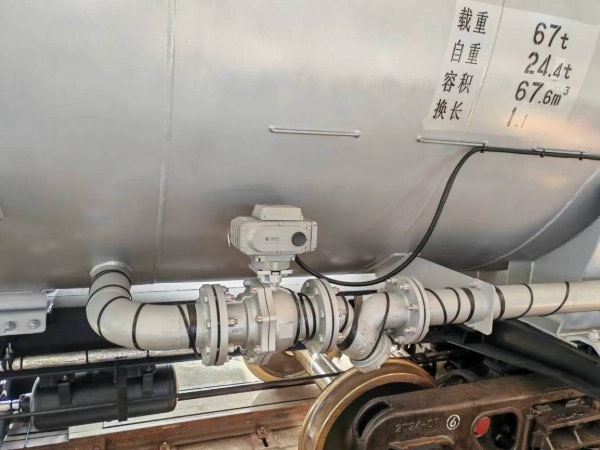

Size: DN65/125

Medium: Water

Working power supply: DC 24V

Temperature: -10°C~ 45°C

Nominal pressure: 1.6MPa

Material: SUS304

Connection: Flange type

Input signal: On/Off

Output signal: passive contacts

Design life: 5-8 years

Operating date: February 2022

Duty station: Public railway system

Product Advantages & Features

High Environmental Adaptability: The SUS304 stainless steel valve body offers excellent corrosion resistance and mechanical strength, while the IP67 protection rating ensures stable operation in high-humidity and salt-spray environments.

Low Power Control: Operates on DC24V power, fully compatible with railway vehicle electronic control systems, featuring low power consumption for opening/closing and ensuring safe and reliable performance.

Fast Response and High Sealing: The ball valve structure enables rapid opening/closing (≤2 seconds) and supports high-frequency operation. Flange connections and a precision ball core design ensure zero leakage at 1.6MPa working pressure, maintaining stable flushing water pressure.

High-Cycle Durability: Designed for continuous railway operation, it utilizes reinforced PTFE seals and requires no maintenance for 12 months or 50,000 operations.

Performance Results

Since its deployment in February 2022, GRAT automation solutions have been widely adopted in water washing vehicles across multiple public railway bureaus, demonstrating the following performance:

Reliability Improvement: Achieves a 100% valve opening/closing success rate with over 12 months of trouble-free operation, significantly reducing maintenance costs.

Optimization of Flushing Efficiency: Electric control enables precise water spray timing, increasing per-vehicle flushing efficiency by approximately 20%.

System Compatibility: Enables seamless integration with existing onboard PLC systems, supporting remote control and status feedback for centralized operation and maintenance management.

GRAT automation solutions, with its exceptional environmental adaptability, precise control performance, and long-lasting stability, has become a key innovative solution in the field of railway insulator water washing. Through continuous technological innovation and strict quality control, we provide smarter and more efficient equipment support for railway operation and maintenance, contributing to the intelligent and green development of China’s railway industry. GRAT will continue to deepen its efforts in the industrial valve sector, creating value for global customers with higher quality products and services while promoting technological advancement in the industry.