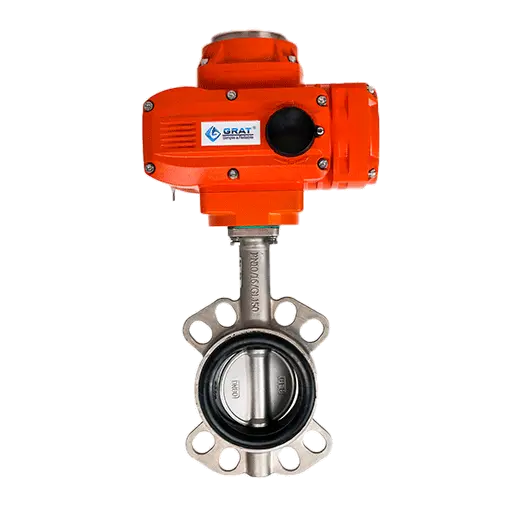

Explosion-proof Electric Butterfly Valve

The Explosion-proof Electric Butterfly Valve is an automated control valve specifically designed for flammable and explosive environments. It combines the compact structure of a wafer butterfly valve with an explosion-proof electric actuator, making it widely used in high-risk industrial sectors such as petroleum, natural gas, and chemical processing.

Tags

Basic Parameters

Nominal Bore (DN):

DN40~800

Operating Power:

AC110V / AC220V / AC380V / DC24V

Medium Temperature:

-20℃~+120℃

Ambient Temperature:

-30℃~+60℃

Nominal Pressure:

0.1~2.5MPa

Actuation Time:

15S / 30S / 60S

Control Method:

Modulating or On/Off Control

Connection & Sealing

Connection Types:

- Wafer Type

- Flange Type

Seal Types:

Soft Seal

Test Pressure - Shell:

1.76MPa

Test Pressure - Seal:

2.4MPa

Material Specifications

Body & Internal Components

Body Material:

WCB, QT450-10, HT200, HT250, SUS304, SUS316

Disc Material:

WCB, QT450-10, HT200, HT250, SUS304, SUS316

Shaft Material:

2Cr13

Sealing Components

Sealing Ring:

Nitrile Oil-Resistant Rubber, EPDM, PTFE, PPL, etc.

Stem Seal:

NBR, HNBR

Packing:

Flexible Graphite

Suitable Media

- Water

- Oil

- Gas

- Corrosive Medium

- Other Media

Explosion Protection

Ex db ⅡC T6 Gb

Flameproof enclosure with increased safety

Explosion Protection

Flameproof (d) + Increased Safety (b)

Gas Group

ⅡC (Hydrogen, Acetylene)

Temperature Class

T6 (≤85°C)

Equipment Protection Level

Gb (Zone 1 & 2)

Standards Compliance

Design:

GB/T 12238-2008

Flange:

- GB/T 9124.1-2019

- GB/T 9124.2-2019

- GB/T 17241.6-2008

Face-to-Face:

GB/T 12221-2005

Testing:

GB/T 13927-2008

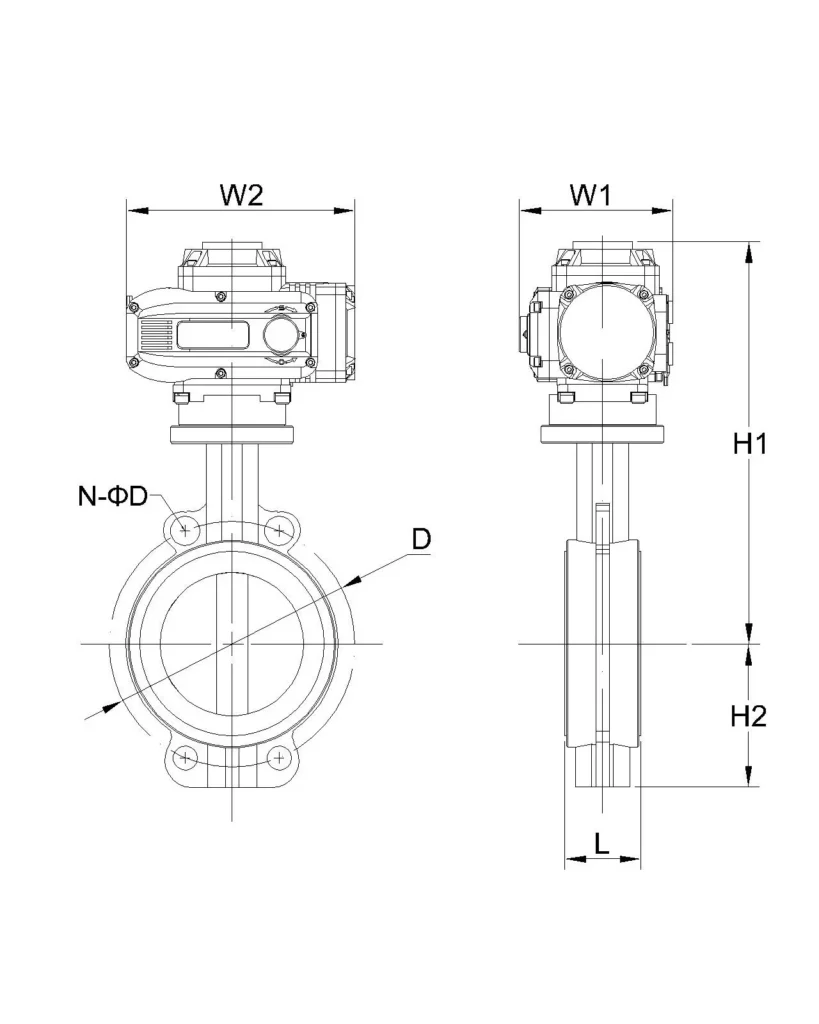

Installation Dimensions of Explosion-proof Electric Butterfly Valve

| Nominal Diameter DN(mm) | L | D | N-ΦD | H2 | H1 | W2 | W1 |

| 40 | 33 | 125 | 4-Φ18 | 48 | 276 | 217 | 150 |

| 50 | 42.6 | 125 | 4-Φ18 | 70 | 398 | 217 | 150 |

| 65 | 45.6 | 145 | 4-φ18 | 76 | 375 | 217 | 150 |

| 80 | 45.6 | 160 | 8-φ18 | 89 | 381 | 217 | 150 |

| 100 | 51.6 | 180 | 4-φ22 | 104 | 414 | 217 | 150 |

| 125 | 55.6 | 210 | 4-φ22 | 120 | 429 | 217 | 150 |

| 150 | 55.6 | 240 | 4-φ23 | 139 | 465 | 217 | 150 |

| 200 | 59.6 | 295 | 4-φ23 | 175 | 536 | 268 | 180 |

| 250 | 67.6 | 355 | 4-φ28 | 203 | 562 | 268 | 180 |

| 300 | 77.6 | 410 | 4-φ28 | 242 | 561 | 268 | 180 |

| 350 | 77 | 470 | 4-φ28 | 277.5 | 562 | 268 | 180 |

| 400 | 86.5 | 525 | 4-φ30 | 309 | 613 | 354 | 273 |

| 450 | 105.6 | 585 | 4-φ30 | 337 | 633 | 354 | 273 |

| 500 | 131.8 | 650 | 4-φ33 | 361 | 693 | 354 | 273 |

Frequently Asked Questions

Find answers to commonly asked questions about our products and services.