Explosion-Proof Electric Hard-Sealed Ball Valve

Hard-sealed electric ball valves are particularly suitable for flow regulation and cutoff of various industrial media requiring high wear resistance and self-cleaning, such as pneumatic-free (mineral slurry, paper pulp) conditions.

Basic Parameters

Nominal Diameter (DN):

DN15-DN350

(For larger diameters, please contact our company for detailed information)

Nominal Pressure:

PN1.6~6.4MPa

Operating Power Supply:

AC110V, AC220V, AC380V, DC24V

Medium Temperature:

≤450℃

Ambient Temperature:

-30~60℃

Control Method:

Modulating or On/Off Control

Actuation Time:

15~120 seconds (0-90°) optional

Dead Band:

0.3%~3.0% adjustable

Connection & Sealing

Connection Type:

Wafer Connection, Flange Connection

Seat Type:

Stainless Steel Movable Hard Seal

Material Specifications

Body & Internal Components

Body Material:

WCB, SS304, SS316, SS316L

Seat Material:

SS304, SS316, SS316L

Valve Core Material:

SS304, SS316, SS316L

Applicable Medium

- Mineral Slurry

- Coal Slurry

- Paper Slurry

- Water

- Oil

- Gas

Explosion Protection

Ex db ⅡC T6 Gb

Flameproof enclosure with increased safety

Explosion Protection

Flameproof (d) + Increased Safety (b)

Gas Group

ⅡC (Hydrogen, Acetylene)

Temperature Class

T6 (≤85°C)

Equipment Protection Level

Gb (Zone 1 & 2)

Standards Compliance

Design & Manufacturing:

GB/T 12237-2007

Flange Standards:

- GB/T 9124.1-2019

- GB/T 9124.2-2019

- GB17241.6-2008

Face-to-Face Dimension:

GB12221-2005

Inspection Standard:

GB/T 13927-2008

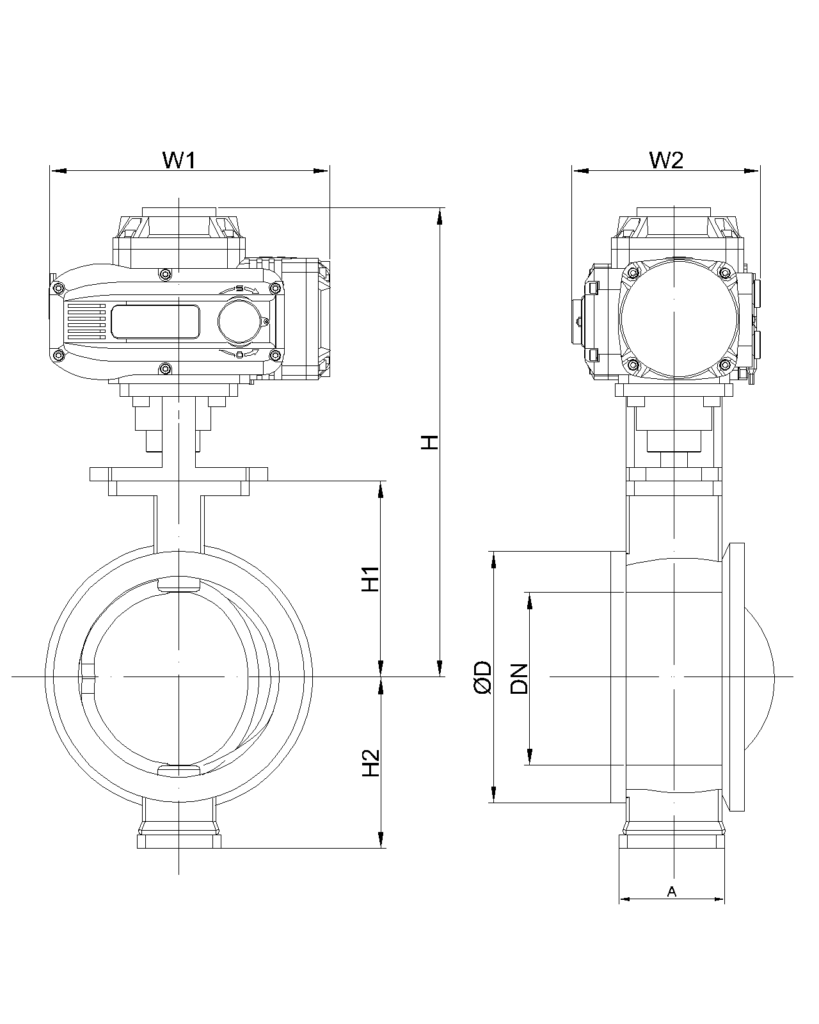

Installation Dimensions of Explosion-proof Electric Ball Valve

| Nominal Diameter (DN) | L | D | K | D1 | n-Φd | b | i | H | W1 | W2 | |

| mm | in | ||||||||||

| 15 | 1/2″ | 130 | 95 | 65 | 45 | 4-Φ14 | 14 | 2 | 220 | 204 | 141 |

| 20 | 3/4″ | 130 | 105 | 75 | 55 | 4-Φ14 | 16 | 2 | 222 | 204 | 141 |

| 25 | 1″ | 142 | 113 | 85 | 65 | 4-Φ14 | 18 | 2 | 230 | 204 | 141 |

| 32 | 1-1/4″ | 165 | 140 | 100 | 78 | 4-Φ18 | 18 | 2 | 244 | 204 | 141 |

| 40 | 1-1/2″ | 165 | 150 | 110 | 85 | 4-Φ18 | 18 | 2 | 245 | 204 | 141 |

| 50 | 2″ | 203 | 165 | 125 | 100 | 4-Φ18 | 20 | 2 | 294 | 252 | 163 |

| 65 | 2-1/2″ | 222 | 185 | 145 | 120 | 8-Φ18 | 20 | 2 | 340 | 252 | 163 |

| 80 | 3″ | 241 | 200 | 160 | 135 | 8-Φ18 | 21 | 2 | 360 | 293 | 184 |

| 100 | 4″ | 305 | 220 | 180 | 155 | 8-Φ18 | 22 | 2 | 379 | 293 | 184 |

| 125 | 5″ | 356 | 250 | 210 | 184 | 8-Φ18 | 22 | 3 | 432 | 293 | 184 |

| 150 | 6″ | 394 | 285 | 240 | 210 | 8-Φ23 | 24 | 3 | 442 | 293 | 184 |

| 200 | 8″ | 457 | 340 | 295 | 265 | 12-Φ23 | 26 | 3 | 507 | 293 | 184 |

Frequently Asked Questions

Find answers to commonly asked questions about our products and services.