Explosion-Proof Electric Short Pattern Ball Valve

The Explosion-Proof Electric Short Pattern Flanged Ball Valve is a high-safety automated valve designed for flammable and explosive environments, featuring a stainless steel or WCB body with PTFE/PPL seals for zero leakage and corrosion resistance, integrated with explosion-certified electric actuators to enable rapid 90° switching or precise flow control. Ideal for oil & gas, chemical,…

Basic Parameters

Nominal Diameter (DN):

DN15 - DN200

Operating Power Supply:

AC110V, AC220V, AC380V, DC24V

Medium Temperature:

-20°C to 350°C

(Special sealing for >200°C)

Working Pressure:

PN16, PN25, PN40, PN64

Control Method:

Modulating or On/Off Control

Protection Class:

IP67

Connection & Sealing

Connection Type:

Flange Type

Sealing Type:

Elastic Seal, High-Temperature Resistant PPS (Polyphenylene Sulfide)

Leakage Rate:

Complies with ANSI B16.104 Class 5 Standard

Material Specifications

Body & Internal Components

Body Material:

WCB, SUS304, SUS316

Ball Material:

SUS304, SUS316

Sealing Components

Seat Material:

PTFE (Normal Temperature)

Special PPL (High Temperature)

Applicable Medium

- Water

- Petroleum

- Nitric Acid

- Acetic Acid

- Viscous Fluids

- Strong Oxidizing Media

Explosion Protection

Ex db ⅡC T6 Gb

Flameproof enclosure with increased safety

Explosion Protection

Flameproof (d) + Increased Safety (b)

Gas Group

ⅡC (Hydrogen, Acetylene)

Temperature Class

T6 (≤85°C)

Equipment Protection Level

Gb (Zone 1 & 2)

Standards Compliance

Design & Manufacturing:

GB 12237-2007, API 6D

Flange Standards:

- JB/T 79-2015

- GB/T 9124.1-2019

- GB/T 9124.2-2019

- ANSI B16.5

- JIS B2239

Face-to-Face Dimension:

GB 12221-2005

Inspection Standard:

API 598

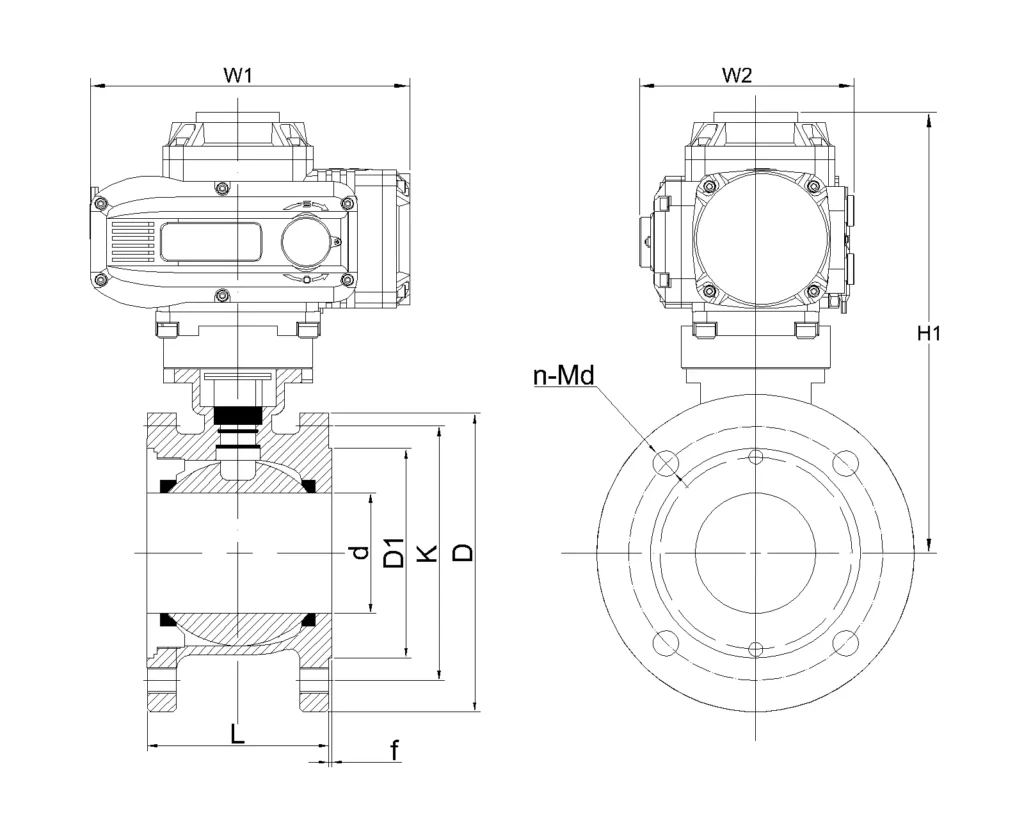

Installation Dimensions of Explosion-proof Electric Ball Valve

| Nominal Diameter (DN) | d | D1 | K | D | n-Md | f | L | H1 | W1 | W2 | |

| mm | in | ||||||||||

| DN15 | 1/2〃 | 15 | 45 | 65 | 95 | 4-M12 | 2 | 35 | 240 | 217 | 150 |

| DN20 | 3/4〃 | 19 | 55 | 75 | 105 | 4-M12 | 2 | 38 | 246 | 217 | 150 |

| DN25 | 1〃 | 25 | 65 | 85 | 115 | 4-M12 | 2 | 50 | 253 | 217 | 150 |

| DN32 | 1-1/4〃 | 28 | 76 | 100 | 140 | 4-M12 | 2 | 50 | 260 | 217 | 150 |

| DN40 | 1-1/2〃 | 38 | 83 | 110 | 148 | 4-M16 | 3 | 67 | 270 | 217 | 150 |

| DN50 | 2〃 | 49 | 102 | 125 | 156 | 4-M16 | 3 | 72 | 279 | 217 | 150 |

| DN65 | 2-1/2〃 | 64 | 120 | 145 | 185 | 4-M16 | 3 | 94 | 325 | 217 | 150 |

| DN80 | 3〃 | 73 | 143 | 160 | 200 | 8-M16 | 3 | 120 | 336 | 268 | 180 |

| DN100 | 4〃 | 90 | 168 | 180 | 220 | 8-M16 | 3 | 141 | 346 | 268 | 180 |

| DN125 | 5〃 | 110 | 185 | 210 | 245 | 8-M16 | 3 | 165 | 421 | 268 | 180 |

| DN150 | 6〃 | 145 | 208 | 240 | 277 | 8-M20 | 3 | 225 | 446 | 268 | 180 |

| DN200 | 8〃 | 195 | 265 | 395 | 335 | 12-M20 | 3 | 275 | 536 | 268 | 180 |

Frequently Asked Questions

Find answers to commonly asked questions about our products and services.