In industrial automation systems requiring 100+ daily cycles, electric actuator slowdown can cripple productivity. A real-world example: An actuator’s cycle time degraded from 15-30s to 45+s within 8 months, costing 20+ minutes of downtime daily. While the OEM denied warranty coverage, our engineering team diagnosed and fixed the issue—here’s how.

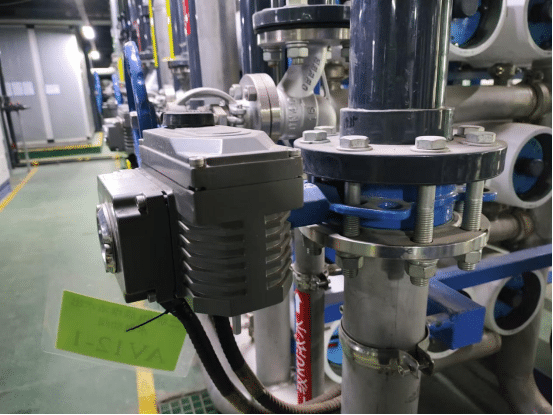

In a reverse osmosis (RO) water treatment system, a DN150 butterfly valve with a 100 Nm electric actuator showed significant performance degradation under high-frequency cycling (80-90 actuations/day)—despite otherwise mild operating conditions.

Medium: Purified water (non-abrasive)

Pressure: Constant 1.18MPa

Valve configuration: DN150 butterfly valve with 100 Nm torque motorized head.

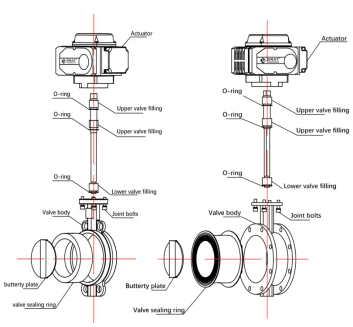

Technical team diagnosis: two core reasons. By analyzing the valve body structure, operating condition data and equipment configuration, we found the following problems:

1.Severe Seat Wear Causing Increased Actuator Torque Demand

The cycle life of national standard (GB) butterfly valves is typically 20,000 to 30,000 cycles, while European standard (e.g., EN) valves achieve 40,000 to 60,000 cycles. The customer operates this valve 80 times per day, totaling nearly 20,000 cycles within 8 months. This usage approaches the end of the valve seat's expected service life.

Consequences of friction: Increased friction between the seat and disc results in a sustained rise in actuator torque requirement and longer stroke times.

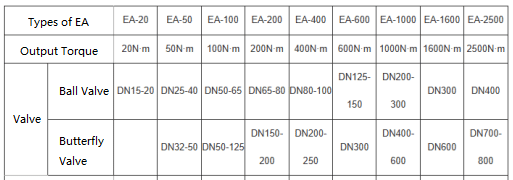

2.The actuator was significantly under-torqued for the application- a classic case of a small horse pulling a heavy cart

The DN150 butterfly valve is usually equipped with a motorized head with 200 Nm torque, but the customer only configured it with 100 Nm.

Direct impact: Long-term overload of low-torque actuators accelerates component aging and further slows down switching speeds.

Optimal Solutions for Valve Maintenance & Performance Enhancement

Option 1: Replace the Worn Valve Seat

If the valve seat is found to be severely worn, directly replace the valve seat with a high wear-resistant material to restore the performance of the valve body and prolong the service life.

Option 2: Upgrade to a Higher-Torque Electric Actuator

If the valve seat is intact, upgrade to a 200 Nm electric actuator to ensure proper torque matching and prevent overloading.

Essential Maintenance Guidelines for High-Frequency Valve Operation

1.Inspect valve seat wear regularly. For valves with over 50 daily cycles, quarterly inspections are recommended.

2.Ensure proper actuator torque matching to prevent premature wear caused by undersized torque of actuators.

3.Select durable valve bodies, such as EN-standard butterfly valves, to significantly extend maintenance intervals.

Grat's Service Commitment

As a professional control valve service provider, we are committed to delivering solutions until the problem is fully resolved. Regardless of warranty status, we offer complimentary technical diagnostics and tailored solutions to ensure efficient and stable production operations.