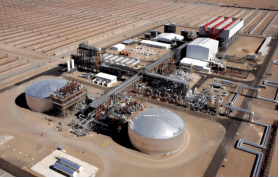

As a key solution for renewable energy storage, molten salt systems face extreme operational challenges 300°C- from 565°C temperatures to corrosive salt flows. Electric high-temperature ball valves serve as critical control components, ensuring both safety and efficiency in these demanding conditions. Grat now Shared some Solutions for a Greener Future.

1.Core Challenges and Valve Requirements in Molten Salt Thermal Energy Storage Systems

Molten salt thermal energy storage systems store and release thermal energy through circulating molten salt (typically nitrate mixtures). This process imposes unique valve requirements:

①Extreme Temperatures: Operating temperatures range from 300°C to 565°C, requiring valves to maintain reliable long-term sealing under continuous thermal stress.

②Medium Characteristics: Molten salt poses risks of solidification-induced clogging and high-temperature corrosion, demanding valves with erosion-resistant materials and anti-clogging designs.

③Precision Control: Rapid flow adjustment is essential for system responsiveness, necessitating valves equipped with high-accuracy electric actuators and tight shut-off capabilities.

2.Three Core Advantages of Electric High-Temperature Ball Valves

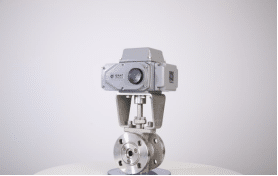

To address the challenges of molten salt systems, electric high-temperature ball valves offer the following key advantages:

①High-Temperature Resistance & Anti-Binding Design

High-Temperature Optimized Construction: The valve body is constructed from high-temperature stainless steel or specialty alloys, paired with graphite/metal hard-sealing for superior thermal stability.

Anti-Binding Mechanism: Preload compensation technology between the ball and seat prevents jamming due to molten salt crystallization or thermal expansion/contraction.

② Intelligent Electric Actuation for Precise Control

High-Precision Regulation: The electric actuator supports 4–20 mA signal feedback and integrates with DCS for real-time (second-level) flow and pressure adjustments.

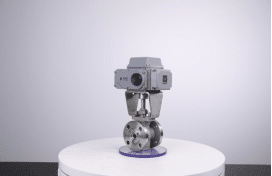

③ Low Maintenance & Extended Service Life

Self-Cleaning Flow Path: A full-bore design minimizes molten salt buildup, reducing clogging risks.

Modular Maintenance: Quick-replacement stem and seal assemblies cut maintenance costs by over 40%.

3.The Critical Role of Electric High-Temperature Ball Valves in Molten Salt Systems

① Energy Storage Phase

Precise Flow Control: Regulates molten salt inflow into storage tanks to prevent overpressure risks.

②Energy Release Phase

Dynamic Flow Adjustment: Modulates molten salt transfer rates to heat exchangers, ensuring stable steam parameters for power generation.

③Safety Protection

Emergency Shutoff: Instantly isolates pipelines during failures to prevent molten salt leaks and associated hazards.

4.Optimizing Valve Selection for Efficient Molten Salt Thermal Storage

With 19 years of expertise in high-temperature valve solutions, Grat Control Valves empowers customers to achieve safe, stable, and long-term operation of thermal storage systems through:

Custom-engineered designs tailored to extreme conditions

Military-grade sealing technology for leak-free performance

Smart control integration for precision and reliability

Within Powering Zero-Carbon Energy with High-Efficiency Molten Salt Systems,Grat cutting-edge electric high-temperature ball valves are engineered to maximize molten salt system performance—delivering unmatched energy storage efficiency, operational reliability, and sustainable energy solutions. By integrating our high-performance valve technology, we ensure seamless thermal energy transfer while driving the next generation of zero-carbon power.

Innovation for a Sustainable Future – Where advanced engineering meets molten salt energy optimization.