During the intelligent upgrade of vessel power systems, precise temperature control is critical for operational safety. Deployed on the LNG Guardian –Grat electric actuators ensure thermal management reliability through high-precision modulation. This project demonstrates the successful integration of electric actuators in premium marine engineering.

Critical Actuator Demands in Offshore LNG Applications

As the "heart" of vessel operations, the shipboard power station requires precise temperature control valve regulation for LNG power system safety and efficiency. This offshore environment presents unique actuator challenges:

Severe Salt Spray Corrosion: Highly corrosive marine atmospheres degrade both metallic and electronic components.

Persistent Vibration & Shock: Continuous mechanical stresses inherent to vessel operations.

Extreme Thermal Cycling: Must withstand temperature extremes from sub-zero seafaring to high-heat machinery spaces.

Zero-Failure Reliability: Power system valve faults risk catastrophic consequences, demanding maintenance-free operation with mission-critical stability.

Marine-Specific Actuator Engineering

Wuhan Grat's electric actuators address offshore demands through purpose-built design:

1.Robust Environmental Protection

IP68 Sealed Enclosure: Pressure-rated sealing against seawater immersion, salt spray corrosion, and particulate ingress.

Marine-Grade Corrosion Resistance: Enhanced with advanced electrophoretic coating, the housing and critical components resist salt and alkali corrosion, ensuring marine-grade durability.

Extended Temperature Operation: -40°C to +100°C functional range for global maritime conditions.

Vibration & Shock Resilience: Structural reinforcement validated against vessel operational stresses.

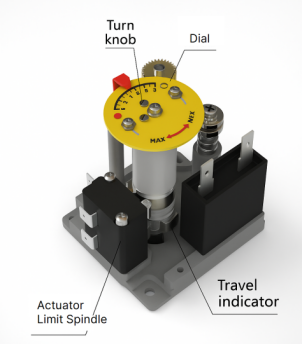

2.Precision Control & Operational Integrity

Challenge: Critical marine valve applications demand extreme precision and reliability under harsh conditions, where even minor deviations can disrupt flow distribution and temperature control in three-way valves.

Grat’s Solution:

±1% Throttling Accuracy: Ensures precise modulation for strict process requirements.

Marine-Grade Reliability: Industrial/ship-certified components guarantee 100,000+ trouble-free cycles.

Integrated Protection Suite: Overload, thermal, and stroke limit safeguards prevent failure while maintaining system integrity.

3.Shipboard Power & Control Integration

Challenge: Vessel systems require rugged, interference-proof connectivity and compatibility with diverse power and control protocols in corrosive, high-vibration environments.

Grat’s Solution:

220VAC Direct Input: Eliminates power conversion needs, matching standard shipboard infrastructure.

Multi-Protocol Signal Support: Native 4-20mA, 0-10V, and discrete interfaces for seamless PLC/DCS/PID integration.

Marine-Proof Connectivity: Water-sealed, shock-resistant connectors ensure uninterrupted electrical performance.

Reliable Power for Open-Ocean Operations

Grat Electric Actuators deliver critical thermal management in the LNG power system of Shipbuilding Heavy Industry Co., Ltd.'s 4,000-horsepower LNG guardian vessel. Proven performance through:

Marine-Optimized Robustness: IP68 sealing, corrosion-resistant construction, -40°C to +100°C tolerance, and vibration-hardened design.

Mission-Critical Control: ≤1% stroke accuracy with 100,000-cycle reliability.

Native Shipboard Integration: 220VAC direct power and standard signal interfaces.

This deployment ensures failsafe actuation of power station thermal regulation valves.