1 Core Principle

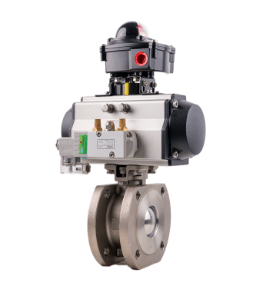

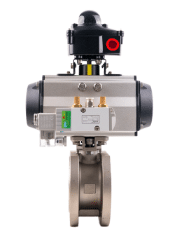

Pneumatic valves control fluid flow (air, gas, or liquids) using compressed air to actuate internal pistons or diaphragms. Unlike electric valves, they're explosion-proof, making them ideal for hazardous environments like chemical plants or oil refineries.

Key Advantage: No electrical sparks ,safer for volatile settings.

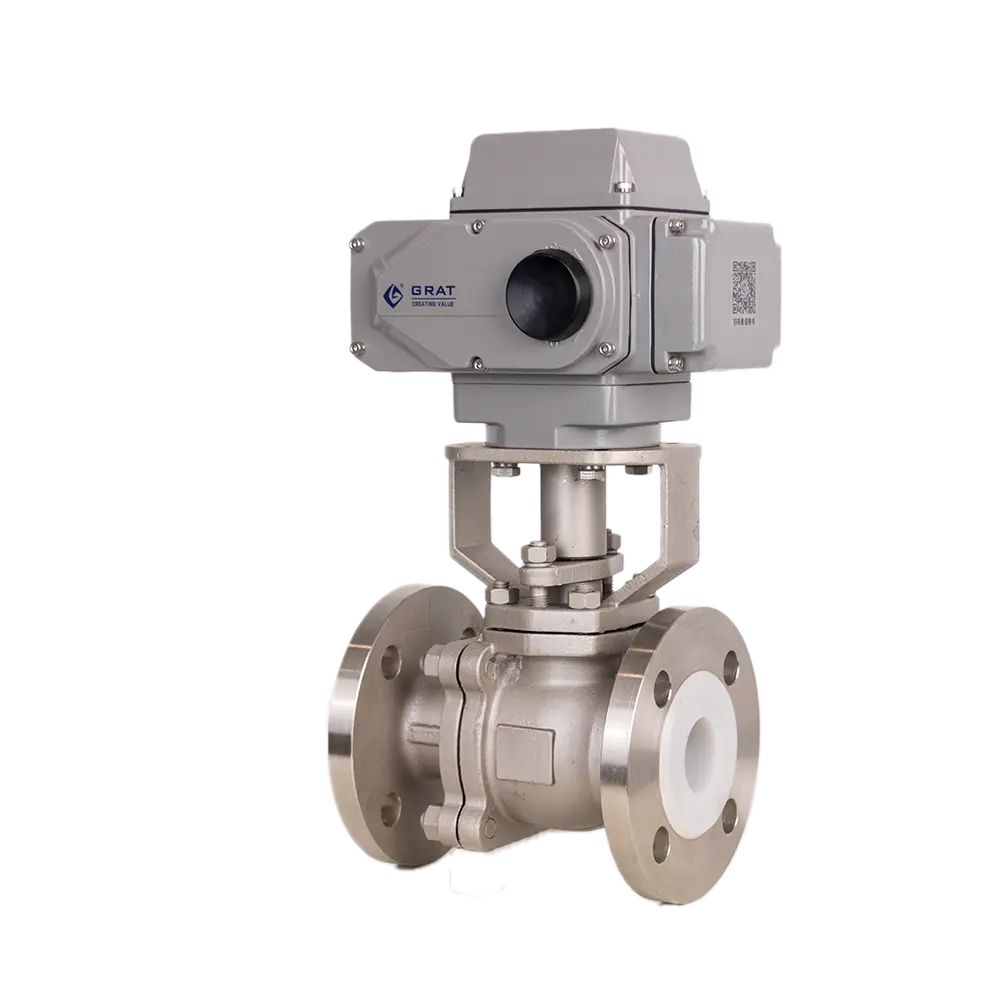

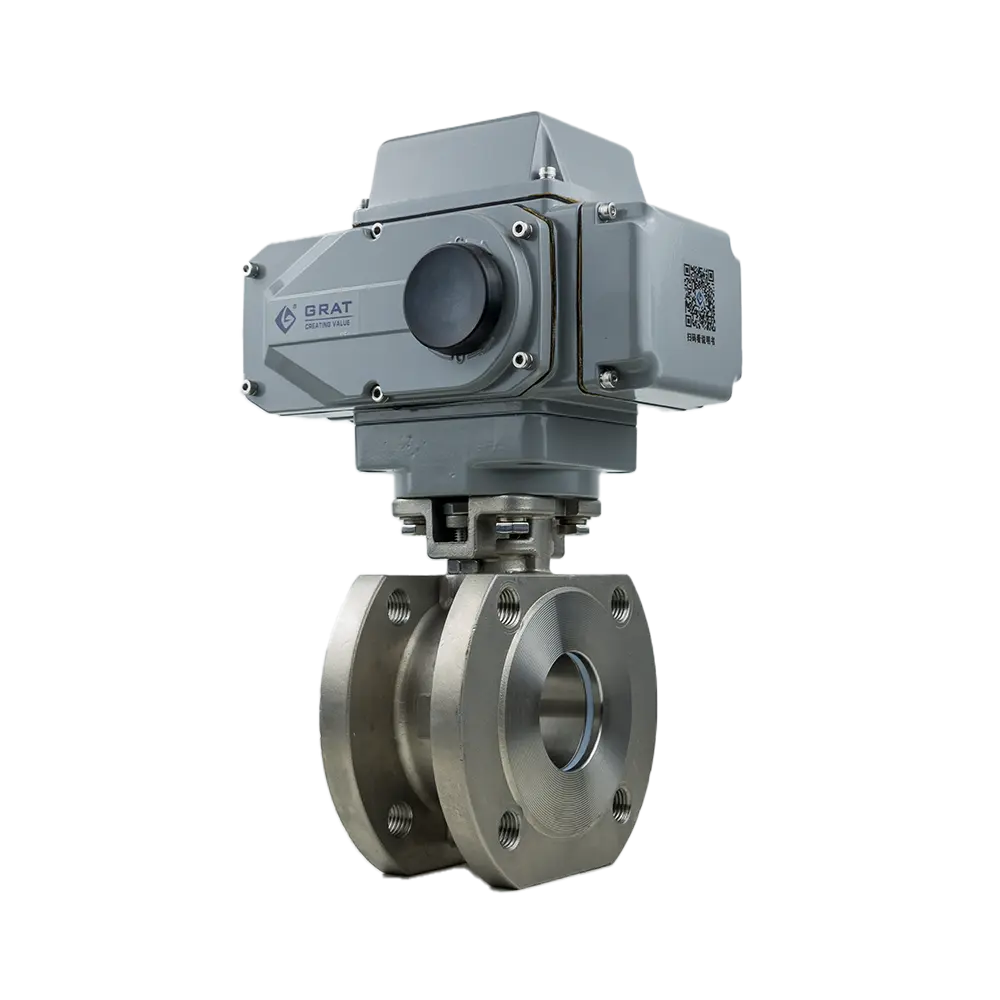

2 Key Components

Actuator: Converts air pressure into linear/rotary motion.

Valve Body: Contains ports and seals to direct flow.

Solenoid (for automated valves): Electrically controls air supply to the actuator.

Why It’s Reliable: Fewer moving parts, lower failure rates vs. hydraulic systems.

3 Compressed Air's Role

Air pressure (typically 20–120 psi) acts on the actuator’s piston/diaphragm. When pressure overcomes spring resistance, the valve shifts. Releasing pressure lets the spring return it to default.

Critical Factor: Air must be clean/dry to prevent corrosion or clogging.

4 Fail-Safe Mechanisms

Many pneumatic valves are "spring-return" – they auto-close if air supply fails (crucial for safety in power plants or chemical systems).

Alternative: Double-acting actuators (air moves valve both ways) for higher speed/force.

5 Speed & Precision

Response time is rapid (milliseconds), but flow control isn’t as precise as electric valves. For accuracy, proportional pneumatic valves modulate air pressure to adjust flow gradually.

Trade-off: Simplicity over precision; best for ON/OFF or coarse control.

6 Real-World Application

Example: In bottling plants, pneumatic valves control air bursts to clean bottles. Their durability and fast cycling outperform electric alternatives.

Takeaway: Pneumatic valves excel where speed, safety, and simplicity matter.